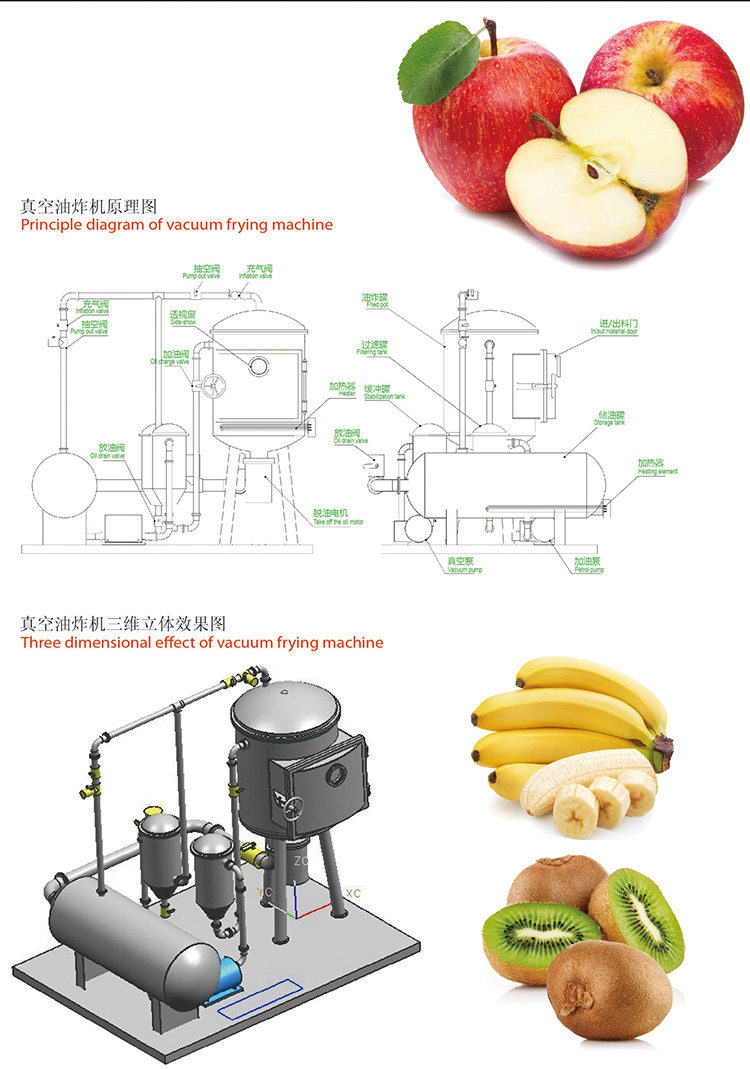

Vacuum Frying Machine

Fruit and vegetable chips processing adopts vacuum frying machine, is described in detail below:

One, the advantages of vacuum frying machine

1, color preserving effect: using vacuum frying, frying temperature greatly reduced, but also reduce the concentration of oxygen in the processing equipment. Fried food is not easy to fade, discolor, Browning, and can keep the color of the fruit and vegetable itself. If such as kiwi fruit Browning, easy to heat by vacuum frying, can maintain its green.

2, taste function: adopt vacuum frying, the raw material is heated in a sealed vacuum condition. The flavor ingredients in most of the raw material for water soluble, does not dissolve in oils and fats, and with the dehydration of raw materials, the flavor ingredients has been further enrichment. Thus the vacuum frying technology is a good way to save the raw material itself has a fragrance.

3, to reduce the oil deterioration degree: oil degradation including oxidation and polymerization, thermal decomposition, and give priority to with water or water vapor and oil contact hydrolysis. In the process of vacuum frying, the oil is in negative pressure condition, dissolve in oils and fats china-germany gas quickly a large number of escape, the vapor pressure is small, and frying temperature is low, as a result, the oil degradation is reduced greatly.

Second, the characteristics of vacuum frying machine process

Vacuum frying is at low temperature (80 ~ 120 ℃) for Fried food, dehydration, can effectively reduce the high temperature damage to the food nutrition.

Vacuum frying oil has the unique effect. At present is mainly used in: (1) fruits: apple, kiwi fruit, grape, persimmon, strawberries, grapes, peaches, pears, etc.; (2) the vegetables: tomatoes, sweet potatoes, potatoes, green beans, mushrooms, mushrooms, garlic, carrot, green pepper, pumpkin, onion, etc.; (3) dried fruit class: jujube, peanut, etc.; (4) of aquatic products andCattle livestock poultry.

Cryogenic vacuum Fried can prevent edible oil degradation is bad, don't need to join other antioxidants, can improve the repeated utilization ratio of oil, reduce the cost. General oil content of Fried food is as high as 40% ~ 50%, and the vacuum oil content of Fried food was 10% ~ 20%, saving 30% ~ 40%, oil-saving effect is remarkable. Food is crisp and not greasy, can storage performance is good.

Cryogenic vacuum Fried can prevent edible oil degradation is bad, don't need to join other antioxidants, can improve the repeated utilization ratio of oil, reduce the cost. General oil content of Fried food is as high as 40% ~ 50%, and the vacuum oil content of Fried food was 10% ~ 20%, saving 30% ~ 40%, oil-saving effect is remarkable. Food is crisp and not greasy, can storage performance is good.

Under the vacuum state, fruits, vegetables, intercellular moisture evaporation, sharply expand, expand clearance, puffing effect is good, crispy and delicious products, and good water resistance.

(fruit and vegetable chips processing equipment) cryogenic vacuum frying machine equipment models

|

Model

|

experimental model

|

ZK-500C | ZK-700C | ZK-900C | ZK-1100C |

| size | Φ320 | Φ500 | Φ700 | Φ900 | Φ1100 |

|

Material basket number

|

1 | 1 | 1 | 1 | 1 |

|

Working temperature

|

80~120 | 80~120 | 80~120 | 80~120 | 80~120 |

|

The vacuum pump power

|

4 | 11 | 11+3 | 11+3 | 11+3 |

|

Heating mode

|

Electrical

|

Electrical/steam

|

Electrical/steam

|

Electrical/steam

|

Electrical/steam

|

|

volume

|

16L | 98L | 192L | 380L | 610L |

|

Loading (French fries, for example)

|

5-7KG/time | 45-50KG/time | 95-100KG/time | 190-200KG/time | 250-260KG/time |

English

English 简体中文

简体中文